Wind power is pretty easy to do in the gusty Great Plains, and through passes and other breezy corridors in the mountainous West – and that’s where the fast-growing renewable energy source has made its greatest strides.

But big parts of the country, where near-surface winds are less amenable to wind power, have been left totally or largely out of the picture.

Now the U.S. Department of Energy wants to change the equation. The way to do that? Go higher.

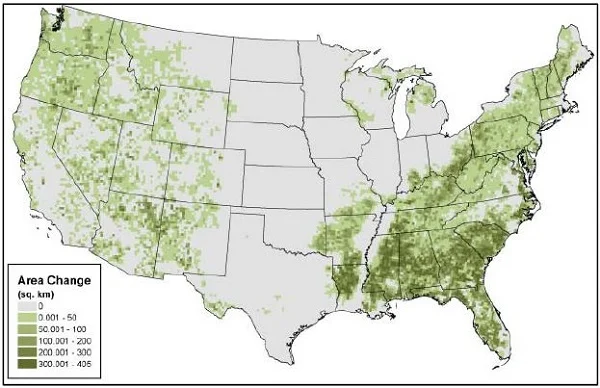

Expanded area of potential wind energy deployment resulting from increasing hub height from 96 meters to 140 meters. (image via DOE)

The DOE on Thursday announced the availability of $2 million in research funding aimed at ratcheting up turbine hub heights. The DOE said the average height of operating turbines today is 90 meters (nearly 300 feet), and the goal is to push that figure up by around 100 feet, to 120 meters. This might sound amazingly high, but it’s where a lot of wind power development in Europe already is: According to data collected by Deutsche WindGuard [PDF], in 2012 the average hub height for turbines installed in Germany, where wind farms are often in forested areas, was 109.8 meters.

There are a several benefits to going higher, and they’ve already motivated developers to push up the average turbine height (see the graphic below). First, the air tends to move more smoothly up high, with less of the turbulence that can not only reduce power output, but can make grid integration more difficult. Second, the wind is often simply stronger at higher altitude. Third, taller towers allow for longer blades, boosting power generating capacity.

Taken together, the DOE, citing research from the National Renewable Energy Laboratory [PDF], says “enabling cost-effective deployment of wind turbines with hub heights up to 140 meters will unlock an additional 1,800 gigawatts in wind power resource potential across 237,000 square-miles of the United States, or an area roughly the size of Texas.”

Average land-based wind turbine size and levelized cost of energy through 2012, and range of state-of-the-art turbines that could be deployed by addressing barriers (image via NREL)

What’s fascinating is that a big part of the challenge the DOE is hoping to address here is a logistical one: how to get taller towers along with other components that likewise would be larger – nacelles and blades – from manufacturing plants to wind farm sites and then installed. From the funding opportunity supporting documents [PDF]:

The potential for continued scaling‐up of wind systems is limited by major components of the latest generation of turbines, particularly towers. These components have become increasingly costly and difficult to transport and install due to increased diameter, weight and length. Current utility‐scale towers are diameter‐constrained by transport limitations, resulting in a much higher steel usage than necessary from an engineering perspective, and restricting the continued growth in scale needed to access better wind resources.

In its announcement, the DOE said it was looking to back two research projects with up to $1 million apiece. The offer comes with a 20 percent cost share requirement.