The development of a new production method could make it possible to manufacture superior-quality, flexible, electronic products at an extremely affordable price.

According to Aalto University in Finland, Professor Yutaka Ohno from Nagoya University in Japan and Professor Esko I. Kauppinen from Aalto University and their research team have created a quick and effortless method of making high-performance, thin-film transistors on plastic substrate. The professors think that the technology for manufacturing semiconducting, carbon nanotube plastic substrates will make it so that companies can manufacture flexible electronic products, such as electronic paper, at a minimal cost.

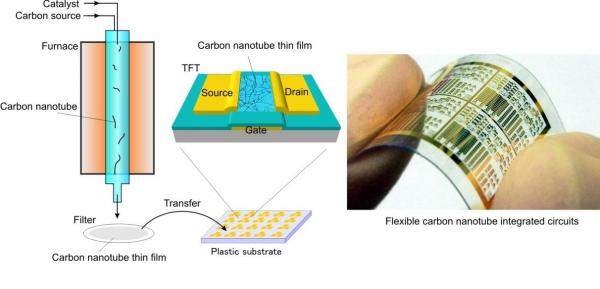

They were able to use the new technology to produce the world’s first successional logic circuits originated from carbon nanotubes.

Lightweight and elastic devices like flexible cellphones and e-paper have become increasingly popular with the development of our information centered society. These machines need flexible electronic components that can be made inexpensively and with ease on a plastic substrate.

In recent years there has been an increase in the use of carbon nanotubes as a transistor substance. This is because of their excellent conduction potential and chemical stability. Nevertheless, even though quite easy solution oriented processes have been created for making nanotube thin-film transistors, the transistors have not reached capability goals in comparison to transistors made from single nanotubes. This is because the conduction properties of the nanotubes break down during the process.

The groundbreaking method relies on growing the nanotubes in atmospheric pressure gas and gathering them with a filter. The results are a thin film which is then transferred from the filter onto plastic, which is able to provide a clean film with uniformity in seconds. This new process is being made into a technology for fast roll-to-roll (R2R) manufacturing

The results of the research were published on February 6 in electronic format in the academic nanotechnology journal, Nature Nanotechnology.