Volvo seems to want to be on the cutting edge of electric vehicle research, despite the fact it doesn’t have that much in the way of actual green car offerings as of yet. It’s already been involved in a project that puts power lines in roads to consistently charge EVs passing overhead, and now it is tinkering with energy storage built directly into car panels.

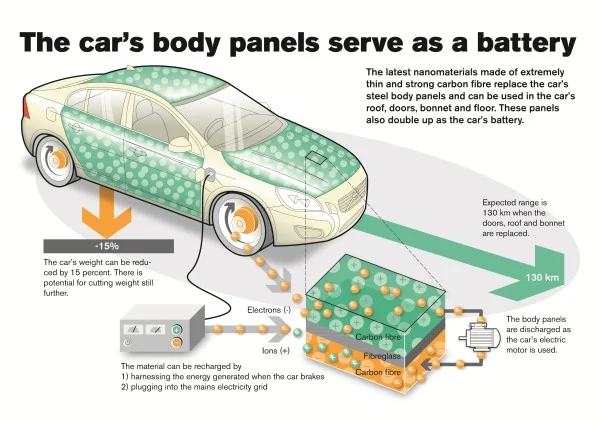

A project that’s funded as part of European Union research, and of which Volvo is the only auto manufacturer involved in, is developing a new concept for lightweight structural energy storage components that could improve the energy usage of electric cars. This concept material consists of carbon fibers, nano structured batteries and super capacitors, and is seen as a future alternative to the heavyweight, large size and high costs associated with the batteries seen in hybrids and electric cars today.

image via Volvo

Already over 3.5 years in development, what’s been created is now realized “in the form of car panels within a Volvo S80 experimental car.” As for the specific technology involved, Volvo spelled it out by saying that the

answer was found in the combination of carbon fibers and a polymer resin, creating a very advanced nano-material, and structural super capacitors. The reinforced carbon fibers sandwich the new battery and are moulded and formed to fit around the car’s frame, such as the door panels, the boot lid and wheel bowl, substantially saving on space. The carbon fibre laminate is first layered, shaped and then cured in an oven to set and harden. The super capacitors are integrated within the component skin. This material can then be used around the vehicle, replacing existing components, to store and charge energy.

The material is recharged and energized by the use of brake energy regeneration in the car or by plugging into a mains electrical grid. It then transfers the energy to the electric motor which is discharged as it is used around the car.

The breakthrough showed that this material not only charges and stores faster than conventional batteries can, but that it is also strong and pliant.

It is believed by Volvo and its partners that the complete substitution of an electric car’s existing components with the new material could cut the overall weight by more than 15%, while “maintaining the efficient capacity of power and performance.” There was no specific mention, however, of when we might expect to see this technology showing up in Volvo cars available for purchase.