Bacteria first discovered in Yellowstone’s hot springs could help produce ethanol from crops such as switchgrass.

At the moment, ethanol production relies on the use of expensive enzymes that break down complex plant materials to yield sugars that are fermented to produce the ethanol.

But what’s known as consolidated bioprocessing – using microorganisms to break down the resistant biomass – could be cheaper and more efficient, says the team.

“Consolidated bioprocessing is like a one-pot mix,” says Oak Ridge National Laboratory’s Richard Giannone.

“You want to throw plant material into a pot with the microorganism and allow it to degrade the material and produce ethanol at the same time.”

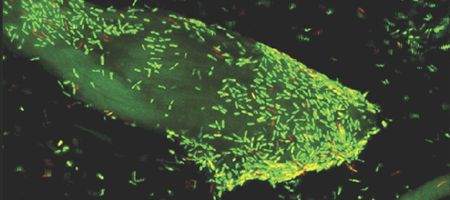

The team’s focusing on Caldicellulosiruptor obsidiansis, a naturally occurring bacterium discovered by BESC scientists in a Yellowstone National Park hot spring.

The microorganism, which thrives at extremely high temperatures, breaks down organic material such as sticks and leaves – making it a natural for biofuel production tanks.

The researchers found that growing the organism on switchgrass prompted it to express an expanded set of proteins dealing specifically with the hemicellulose content of the plant.

Once inside the cell, the organism switches on certain enzymes involved in pentose metabolism in order to further process these hemicellulose-derived sugars into usable energy.

“By comparing how C. obsidiansis reacted to switchgrass, relative to pure cellulose, we were able to pinpoint the specific proteins and enzymes that are important to plant cell wall deconstruction — a major roadblock to the production of advanced biofuels,” says Giannone.