Engineers at Vanderbilt University say they’ve found a new cooling technology for computer chips, lasers and other devices.

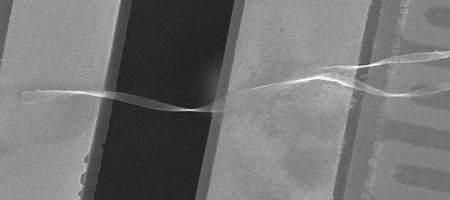

Deyu Li, associate professor of mechanical engineering, and his team have found that the thermal conductivity of a pair of thin strips of material called boron nanoribbons can be enhanced by up to 45 percent depending on how the two ribbons are stuck together.

The results should apply to other thin film materials too, says the team.

“This points at an entirely new way to control thermal effects that is likely to have a significant impact in microelectronics on the design of smart phones and computers, in optoelectronics on the design of lasers and LEDs, and in a number of other fields,” says Greg Walker, associate professor of mechanical engineering at Vanderbilt.

The two nanoribbons together are held together by a weak electrostatic attraction called the van der Waals force – the same force that allows geckoes to walk up walls.

“Traditionally, it is widely believed that the phonons that carry heat are scattered at van der Waals interfaces, which makes the ribbon bundles’ thermal conductivity the same as that of each ribbon,” says Li.

“What we discovered is in sharp contrast to this classical view. We show that phonons can cross these interfaces without being scattered, which significantly enhances the thermal conductivity.”

The team found that they could control the thermal conductivity between a high and a low value by treating the interface of the nanoribbon pairs with different solutions.

And the effect is reversible: for example, when the researchers wetted the interface of a pair of nanoribbons with isopropyl alcohol, pressed them together and let them dry, the thermal conductivity was the same as that of a single nanoribbon.

However, when they wetted them with pure alcohol and let them dry, the thermal conductivity was enhanced. Wetting them with isopropyl alcohol cut the thermal conductivity back to the original low value.

One of the first applications is likely to be in the thermal management of microelectronic devices like computer chips. With billions or even trillions of transistors jammed into chips the size of a fingernail, preventing overheating has become a major factor in their design.

Indeed, heat management is one of the major reasons behind today’s multi-core processor designs.

Another area where the technique could be used is in the design of nanocomposites – materials made by embedding nanostructure additives such as carbon nanotubes to a host material such as various polymers.

These are being developed for use in flexible electronic devices, structural materials for aerospace vehicles and a variety of other applications.