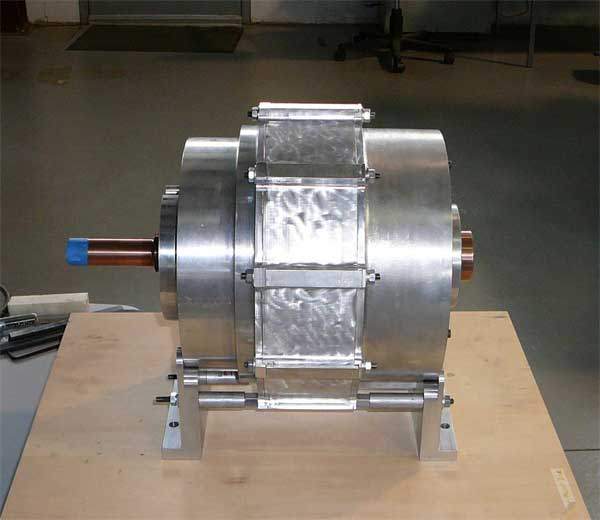

General Electric (GE) has been working to create a more efficient electric motor for battery-powered EVs and hybrid vehicles.

Recently, the auto manufacturer announced the development of a prototype electric motor with a higher power density that delivers improved acceleration and is more energy efficienct than current models on the market.

The most interesting aspect of the new electric motor? It is capable of delivering the above-mentioned improvements in a smaller frame and at a lower cost than current-gen motors.

The prototype also boasts almost twice the temperature tolerance of a conventional hybrid-electric motor and doesn’t require a separate cooling system. As you may recall, most electric motors available today require their own standalone cooling system – adding both complexity and weight to the average auto equation. Clearly, less weight means the driving range of EVs can be significantly extended.

Indeed, GE believes its new motor will have a substantial impact on hybrid and electric vehicles in the future. The prototype uses Interior Permanent Magnet technology – developed as part of a $5.6 million US Department of Energy project – and features a peak power level of 55 kW, along with an improved efficiency level of at least 3-5%. The required torque is achieved at a DC bus voltage of 200 V compared to 650 V required for existing electric motors.

“This is a significant accomplishment. We are pushing the boundaries to build more robust, yet more efficient motors for hybrid and fully electric platforms,” GE engineer Ayman El-Refaie explained. “We have built a motor that is substantially more powerful than what’s commercially available now, all while improving efficiency by up to 5%.”

GE says that conventional traction motors run at 65°C and require their own dedicated cooling loop. The GE prototype motor operates continuously at 105°C over a wide speed range of 2800 to 14,000 RPMs and is cooled with existing engine coolant.

“This technology is scalable and flexible enough that it can be leveraged in a number of capacities… What we learned through this project will help us build higher efficiency industrial motors, high-speed oil and gas compressor motors, and generators for aerospace applications,” El-Refaie added.