Researchers at the University of Leeds say that a type of bacterium which ‘eats’ iron to create tiny magnets could be used to make larger hard drives and faster connections.

Together with researchers from the Tokyo University of Agriculture and Technology, the team hopes to develop a ‘bottom-up’ approach for creating cheaper, more environmentally-friendly electronics of the future.

“We are quickly reaching the limits of traditional electronic manufacturing as computer components get smaller,” says Leeds’ Dr Sarah Staniland.

“The machines we’ve traditionally used to build them are clumsy at such small scales. Nature has provided us with the perfect tool to circumvent this problem.”

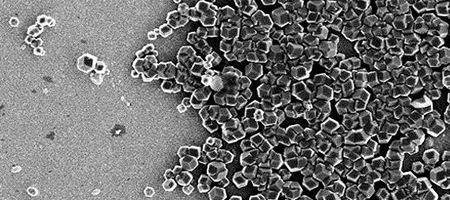

The magnetic array was created using a protein which creates perfect nanocrystals of magnetite inside the bacterium Magnetospirilllum magneticum. This protein is attached to a gold surface in a checkerboard pattern and placed in a solution containing iron.

At a temperature of 80°C, similarly-sized crystals of magnetite form on the sections of the surface covered by the protein.

The team’s now working to cut down the size, to make arrays of single nanomagnets, and vary the magnetic materials that this protein can control. This would allow each nanomagnet to hold one bit of information, allowing the construction of better hard drives.

“Using today’s ‘top-down’ method – essentially sculpting tiny magnets out of a big magnet – it is increasingly difficult to produce the small magnets of the same size and shape which are needed to store data,” says PhD student Johanna Galloway.

“Using the method developed here at Leeds, the proteins do all the hard work; they gather the iron, create the most magnetic compound, and arrange it into regularly-sized cubes.”

A different protein has been used to create tiny nanowires, made of ‘quantum dots’ – particles of copper indium sulphide and zinc sulphide which glow and conduct electricity – encased by fat molecules, or lipids.

“It is possible to tune these biological wires to have a particular electrical resistance. In the future, they could be grown connected to other components as part of an entirely biological computer,” says Tokyo’s Dr Masayoshi Tanaka.

The team now plans to examine the biological processes behind the behaviour of these proteins.

“Our aim is to develop a toolkit of proteins and chemicals which could be used to grow computer components from scratch,” says Dr Staniland.