The next iteration of the iPhone is likely to be the slimmest one yet.

That probably doesn’t surprise anyone. After all, Apple is always on a mission to make the sleekest consumer electronics products on the planet. It is noteworthy to discuss exactly how the company may go about achieving that goal, though.

At the forefront of Apple discussions, opines KGI Securities analyst Ming-Chi Kuo, is “in-panel” technology that would allow the company to integrate both the touch sensor and the actual LCD panel in one component.

As the iPhone construction stands now, these two parts of the phone are separate pieces, meaning the touch sensor is an individual component that sits on top of the display itself.

If it could combine those into one piece of technology, it would be able to shave off a significant chunk of the device’s size. Keep in mind we’re already talking about a very thin phone, so a “significant chunk” could just be a couple tenths of a millimeter.

In addition to making a sleeker phone, though, this would also help Apple with production. It could potentially cut back the lead time to make an iPhone from around two weeks to just 3 – 5 days.

The reason this has not been implemented in earlier iPhone designs is that the technology just wasn’t quite there yet and would have added on too much of an unnecessary cost. In the long run, though, it might now be at the point where doing so would actually save money for Apple.

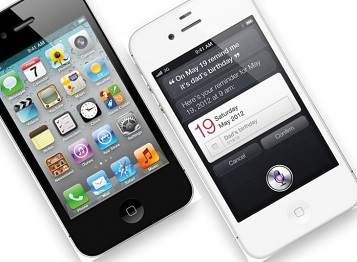

Kuo also believes the Apple will continue to optimize its battery size, and change from a glass back panel to a metal panel in order to cut back on device size. These advancements, he says, will potentially lead to an iPhone 5 that is 0.44 millimeters smaller than the iPhone 4S.