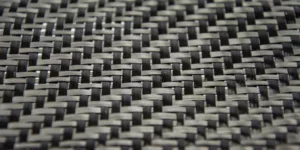

There are times when fabricators working with composite materials need a better solution than manual layups. A better solution is often found in prepregs, a specific form of composite material that is already impregnated with the necessary resin solution and curing agent. Prepregs can be used in place of manual layups or in combination with them, as the fabricator sees fit.

Prepregs are quite a bit more expensive compared to using the same composite materials in a manual layup scenario. But they are still very much in demand, as evidenced by the 20 distinctive styles of prepregs sold by Utah-based Rock West Composites. As a leading provider of composite materials to fabricators, Rock West puts a heavy emphasis on prepreg products. In fact, they just announced a new line of materials for the prepreg market.

As a fabricator yourself, there are five excellent reasons you might choose prepregs over manual layups:

1. Better Resin/Fabric Balance

Fabricators already know how difficult it is to achieve the correct resin content in a manual layup. For those applications that are especially sensitive to this balance, prepregs are the answer. Most prepregs are impregnated with 35% resin, making it much easier to achieve the correct balance during the curing process. Fabricators have very few problems with excess resin that can throw off the delicate balance. As an added bonus, the correct resin/fabric balance results in superior strength in the finished product.

2. Product Consistency

Prepreg materials offer robust consistency, especially when they all come from the same manufacturer. Such consistency may be critical when uniformity and repeatability are important to a given project. Fabricators can rely on prepregs to deliver the same results – piece after piece and cycle after cycle. Furthermore, prepregs reduce the margin of error that must be built into vacuum bagging.

3. Less Waste

It is no secret that manual layups create a certain amount of waste in excess resin. Unfortunately, the excess resin is not easily reusable which, in effect, loses money. Most of the waste is eliminated with prepregs. Additional waste is avoided in that prepregs are easier to use without having to worry about resin setting up too quickly.

4. Shorter Curing Times

Manual layups require a full curing time of up to 48 hours due to the unevenness of the resin saturation. Because prepregs come fully and evenly saturated from the manufacturer, this is not an issue. Most parts fabricated from prepregs can be used immediately after the completion of the heat curing process. There is no need to wait the extra time.

5. Superior Finish

Lastly, fabricators whose projects are especially sensitive to finish love prepregs because they all but eliminate air bubbles and other imperfections. Parts emerge from their molds needing very little touch up work before a finish is applied. That makes prepregs great for projects in which a glossy finish is preferred.

Final Thoughts about Prepregs

Rock West Composites fully endorses the use of prepregs for certain kinds of projects that require greater consistency and better finish. However, they remind their clients that prepregs products are not for beginners. While it is possible for less experienced fabricators to use prepregs, it really helps to have a comprehensive knowledge of composite materials by way of manual layups before prepregs are even considered.

Prepreg products can be used in a wide variety of industries including aerospace, sporting goods, maritime operations, auto racing, and commercial manufacturing. Though prepregs are more expensive than manual layups, they give fabricators yet another tool to create the precision that finished products composites are known for.