Climbing robots that mimic the stickiness of gecko lizard feet could work in space as well as on Earth, ESA has shown, raising the prospect of hull-crawling automatons tending future spacecraft.

Robots crawling across spacecraft surfaces are a common sight in science fiction films from Silent Running to Wall-E. But, in reality, how might they stick in place while still remaining mobile?

Researchers from ESA and Simon Fraser University in Canada subjected gecko-inspired ‘dry adhesive’ materials to space vacuum and temperatures, finding the stickiness is retained throughout.

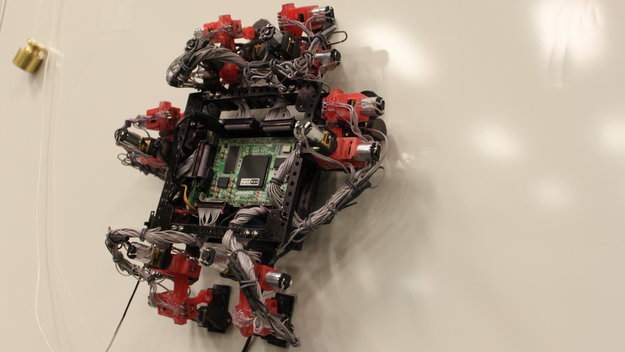

Engineers from the University’s School of Engineering Science have demonstrated such adhesives with a family of ‘Abigaille’ crawling robots.

“This approach is an example of ‘biomimicry’, taking engineering solutions from the natural world,” explained Michael Henrey of Simon Fraser University.

A gecko’s feet are sticky due to a bunch of little hairs with ends just 100–200 nanometres across – around the scale of individual bacteria. This is sufficiently tiny that atomic interactions between the ends of the hairs and the surface come into play.

“We’ve borrowed techniques from the microelectronics industry to make our own footpad terminators,” he said. “Technical limitations mean these are around 100 times larger than a gecko’s hairs, but they are sufficient to support our robot’s weight.”

Interested in assessing the adhesive’s suitability for space, Michael tested it in ESA’s Electrical Materials and Process Labs, based in the Agency’s ESTEC technical centre in Noordwijk, the Netherlands, with additional support from ESA’s Automation and Robotics Lab.

“The reason we’re interested in dry adhesives is that other adhesive methods wouldn’t suit the space environment,” Michael notes.

“Scotch, duct or pressure-sensitive tape would collect dust, reducing their stickiness over time. They would also give off fumes in vacuum conditions, which is a big no-no because it might affect delicate spacecraft systems.

“Velcro requires a mating surface, and broken hooks could contaminate the robot’s working environment. Magnets can’t stick to composites, for example, and magnetic fields might affect sensitive instruments.”

“A depth-sensing indentation instrument was used inside a vacuum chamber to precisely assess the dry adhesive’s sticking performance,” said ESA’s Laurent Pambaguian. “Experimental success means deployment in space might one day be possible.”

“It’s very expensive to upgrade hardware once it is up in space so the idea would be to fly a more general robot in the first place,” Michael said. “This could then be adapted through software upgrades for different tasks that weren’t anticipated at the start of the project.

“Our Abigaille climbing robot is therefore quite dexterous, with six legs each having four degrees of freedom, so it should be handle environments that a wheeled robot could not.

“For example, it can transition from the vertical to horizontal, which might be useful for going around a satellite or overcoming obstacles on the way.”

Robotic wall-crawling is limited to relatively smooth man-made surfaces for now, with research continuing to improve performance.

The cooperation took place through ESA’s Networking/Partnering Initiative, which supports work carried out by universities and research institutes on advanced technologies with potential space applications.