An international team of scientists has designed a multi-component molecular motor that can be moved clockwise and counterclockwise.

Although researchers are currently capable of rotating or switching individual molecules on and off, the above-mentioned initiative is the first to create an actual stand-alone molecular motor with multiple components.

According to Saw-Wai Hla, an Ohio University professor of physics and astronomy, the molecular motor represents an essential step in creating functioning nanoscale devices – quantum machines that operate on different laws of physics than classical machines.

Indeed, scientists envision nanoscale devices being used for everything from powering quantum computers to clearing dangerous blood clots in arteries.

“[We] controlled the motion of the motor with energy generated by electrons from a scanning tunneling microscope tip,” Hla explained. “The motor is about 2 nanometers in length and 1 nanometer high and was constructed on a gold crystal surface.”

As Hla notes, at a temperature of minus 315 degrees Fahrenheit, the motor could move independently through thermal excitation. However, when scientists cooled the sample to minus 450 degrees, the motor stopped rotating. The researchers then selectively applied electron energy to different parts of the motor to prompt it to move clockwise and counterclockwise.

“If we want to build an actual device based on this motor, we would install electrodes on the surface to create an energy source,” Hla said.

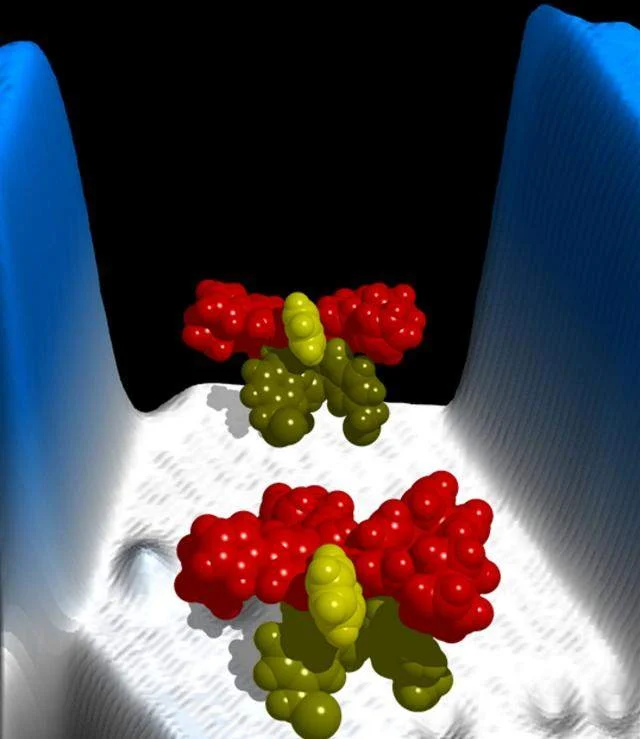

To construct the molecular motor, the scientific team designed a stationary base of atoms that is connected to an upper moving part by one atom of ruthenium, which serves as the “ball bearing.”

The upper piece of the motor features five arms made of iron atom, with one arm shorter than the others to accurately track the motion of the machine. The entire device is held upright by using sulfur as an “atomic glue” to secure the motor to the gold surface.

“[We] now plan to use the above-mentioned model to build more complex machines with components that could be automated,” Hla added.