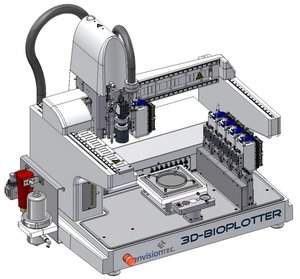

The 3D-Bioplotter takes computer aided designs from a PC and build biomaterials. Anxious geeks building girlfriends in AutoCAD as we speak.

Germany company, envisionTEC, has developed a Rapid Prototyping tool for processing biomaterials. Using a process called Computer Aided Tissue Engineering, which has nothing to do with Kleenex but everything with us, the Bioplotter can fabricate 3D scaffolds made up of various biomaterials from soft hydrogels to hard ceramics and metals.

Soft tissue fabrication, the notion of building human organs, can be achieved using scaffolds built on Agar, Gelatine, Collagen, Chitosin, Alginate, and Fibrin. Currently, the printer is being used to create biogradable scaffolds used for custome bone implants.

In an interview given to Doug Smock at Design News, during Rapid 2010, Dr. Vladimir Mironov, director of the Advanced Tissue Biofabrication Center at the Medical University of South Carolina, said that one of the long term goals is to print human organs such as kidneys and livers.

Tissue engineering is a promising solution to the problem of tissue or organ shortage. The notion that we can manufacture organs, bones, and skin is not a pipe dream, but a possibility. In a very simplistic terms, because I am a simpleton, a matrix of nanotubes made from a variety of biomaterials can be organized in such a way as to coalesce or attract other organic matter and build into engineering tissue, whether it be a blood vessel, or eventually, the ultimate prize, an organ.

Would be Frankensteins and Re-Animators (props and much love to H.P. Lovecraft, people) will need a little under $200,000 to get this baby.