Boeing’s CST-100 spacecraft is one step closer to liftoff after a gauntlet of test firings of its steering jets at White Sands Space Harbor in Las Cruces, N.M.

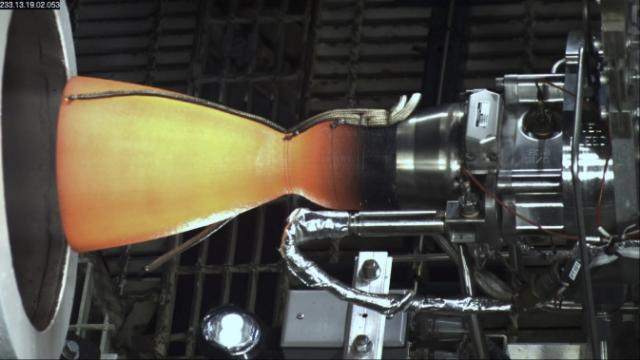

Boeing and Aerojet Rocketdyne recently completed the tests, which simulated the demanding environment of space. The tests assessed how the thrusters — which fire with 1,500 pounds of force — will speed up, slow down and move the spacecraft while carrying NASA astronauts in Earth’s orbit.

Boeing is developing a fully integrated crew transportation system, which includes the CST-100 spacecraft and the United Launch Alliance Atlas V rocket, in partnership with NASA’s Commercial Crew Program (CCP). New commercial spaceflight capabilities being developed by NASA partners through commercial crew initiatives eventually could provide services to transport astronauts to and from the International Space Station, launching from American soil. Boeing is working on development milestones that are part of NASA’s Commercial Crew Integrated Capability (CCiCap) initiative.

“Boeing and Aerojet Rocketdyne continue to show a path forward for NASA’s low-Earth orbit crew transportation needs by implementing cutting-edge technologies and showcasing decades of human spaceflight experience,” said Ed Mango, CCP manager.

The CST-100’s orbital maneuvering and attitude control (OMAC) system has 24 thrusters, giving it the ability to perform critical maneuvers in space such as those required to refine the CST-100’s orbit, as well as the braking maneuver near the end of a mission that slows the spacecraft down before re-entry. The OMAC thrusters will be jettisoned when the service module is released from the capsule just before re-entry. Positioned in four clusters of six on the service module of the spacecraft, the thrusters could steer the spacecraft in case an emergency calls for it to separate from its rocket during launch or ascent.

During the tests, the OMAC thrusters were fired in a vacuum chamber that simulated the space-like environment at an altitude of 100,000 feet. These evaluations put the thrusters through the burns and stresses they would encounter during a real flight. Engineers equipped the jets with a host of instruments to measure changes in the smallest components.

“The CST-100 OMAC thrusters are an example of leveraging proven flight hardware solutions to ensure mission supportability,” said John Mulholland, Boeing vice president and manager for commercial programs. “We are very pleased with the data collected during this second series of tests and with our overall team performance as we continue to progress through CCiCap milestones on time and on budget.”

Previous tests of the OMAC thrusters verified their durability in extreme heat, evaluated the opening and closing of their valves and confirmed continuous combustion and performance. Designers are using the results of these tests to validate or adjust their complex computer models that predict how a thruster and spacecraft will work during a mission.

“The OMAC engines met CCiCap test objectives,” said Terry Lorier, Aerojet Rocketdyne’s CST-100 Service Module Propulsion Program manager. “Aerojet Rocketdyne and Boeing are both pleased with the results and look forward to continuing our partnership.”

With the completion of Milestone 9, Boeing is on track to meet all 20 of its CCiCap milestones by summer 2014. All of NASA’s industry partners, including Boeing, continue to meet their established milestones in developing commercial crew transportation capabilities.