A new, high-precision 3D printer can create nanometer-sized objects and is way faster than similar devices.

The Vienna University of Technology printer uses a liquid resin, ardened at precisely the right spots by a focused laser beam. The focal point of the laser beam is guided through the resin by movable mirrors to leave behind a hardened line of solid polymer, just a few hundred nanometers wide.

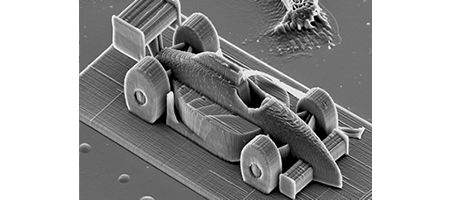

It makes it possible to create intricately structured sculptures as tiny as a grain of sand.

“Until now, this technique used to be quite slow,” says Professor Jürgen Stampfl from TU Vienna. “The printing speed used to be measured in millimeters per second – our device can do five meters in one second.”

As well as improving the steering mechanism of the mirrors, the team altered the chemistry of the resin. When molecules are activated by the laser light, they induce a chain reaction in other components of the resin, so-called monomers, and turn them into a solid.

This means that, in contrast to conventional 3D-printing techniques, solid material can be created anywhere within the liquid resin rather than on top of the previously created layer only. The working surface doesn’t have to be specially prepared before the next layer can be produced, saveing a lot of time.

The dramatically increased speed means that much larger objects can now be created in a given period of time – making two-photon-lithography more useful for industry.

The TU Vienna team is now developing bio-compatible resins for medical applications, creating scaffolds to which living cells can attach themselves.